Before building a part out of ABS (because it has to be strong but not brittle) on my Metal Plus, I ran the hot end up to 225C and told octoprint to extrude a bunch of filament. I ran it until the clear PCTPE I’d used for the previous print stopped coming out and the yellow ABS I was using for this one had coming out for a while.

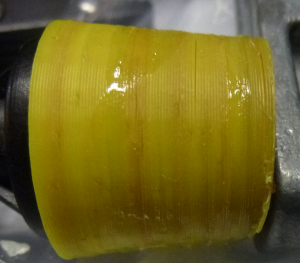

Then I started the part running and monitored it by browser from the other end of the house. Perfectly fine print. But when I got down to the basement, it turned out there were a bunch of layer delaminations, each marked by a line of red filament that I am pretty sure was the PLA that I used on the last job but one. The last of these cracks came after about 6 cm^3 of ABS had been extruded.

So do I just have too much dead space in the hot end? (I promise, I cranked the nozzle on as tightly as I felt safe.) Are these kinds of dribs and drabs usual? I don’t typically switch back and forth that much. Should I just use the other extruder or swap in a different hot end when I’m using a different filament?

Or do I have a dirty drive gear? I find it hard to believe that bits of PLA would stick in the crevices of the gear and then embed themselves in the ABS and get carried down to the hot end in quantities sufficient to make those red lines, but I don’t know. (I do know that when I was playing with black filaments the other day, it took a cm^3 or two after switching to another color before anything came out that even looked dark grey…)

Or do I have a dirty drive gear? I find it hard to believe that bits of PLA would stick in the crevices of the gear and then embed themselves in the ABS and get carried down to the hot end in quantities sufficient to make those red lines, but I don’t know. (I do know that when I was playing with black filaments the other day, it took a cm^3 or two after switching to another color before anything came out that even looked dark grey…)

Any ideas? How much purging do other people do?