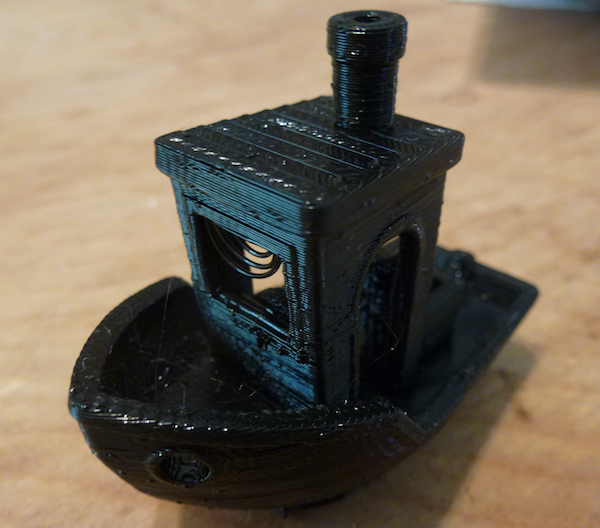

(PET+, 250 degrees, .25mm layer height, 60 mm/sec, no additional acceleration control)

(PET+, 250 degrees, .25mm layer height, 60 mm/sec, no additional acceleration control)

I think I know what most of the other issues are — the blebs are from not retracting enough on layer change, the ringing is from running too fast, the general unsharpness is from extruding too much and probably too hot without enough fan. This is the profile I use for banging out utility prints, and I wanted to see how it would do before tightening things up.

But those loops in the front window don’t make sense to me. The bridging on the roof did just fine with no sagging, and the inner and outer perimeters are fine too, it’s just one strand from each layer that sagged down. I guess maybe the middle strand wasn’t touching its neighbors and was still hot when the next layer went on top of it, but that doesn’t really explain why something similar didn’t happen with the roof. Any thoughts?