Even without a magnifier, my old eyes and fingers can deal with some of the bigger SMT LED packages. I’ve been doing some tests to figure out the best way to mount and connect these. A couple dabs of wire glue applied with a syringe definitely do the trick (although the stuff takes an hour plus to dry) but getting anything else to make good contact with the glue trace is, uh, difficult. And resistance, as we know, is high.

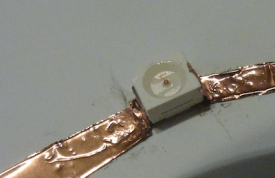

I tried two different methods with copper tape: one with the tape adhering to the contacts and burnished in as hard as I could manage, the other with a dot of glue holding the LED in place and then a folded-over end of tape mashed against each contact to get a metal-to metal connection.

Both methods work. I was surprised at how well the tape holds — you could probably even use it to suspend an LED in midair if you were so inclined. The glue-dot method makes the LED much easier to handle, though, and the resistance is a bit lower when the copper is actually touching the led. So maybe a fast-drying glue, then some burnishing once everything is in place? I’m not sure, but I do know I like this better trying to coerce through-hole LEDs and their wires to lie flat and behave.

UPDATE: This afternoon the circuitscribe pens I backed on Kickstarter way back when finally arrived. So I drew a few lines. Yes, you can extend copper-tape line with the silver ink. No, it doesn’t really connect reliably to the wire glue (burnished copper tape does better). Yes, drawing some wires on paper and plopping an LED on top works, as long as the led doesn’t slide away (still need some kind of infinitesimally thin dot of glue). At roughly $20 a pen and a rated 60-80 meters of line per, the cost is lower than Adafruit’s copper tape, but not if you take your scissors and slice the tape in half lengthwise. But still: wow.