Dunning and Krueger strike again. I thought I knew the retail PC industry well enough, just because I’ve chatted with so many of the people who invented it. But times have changed.

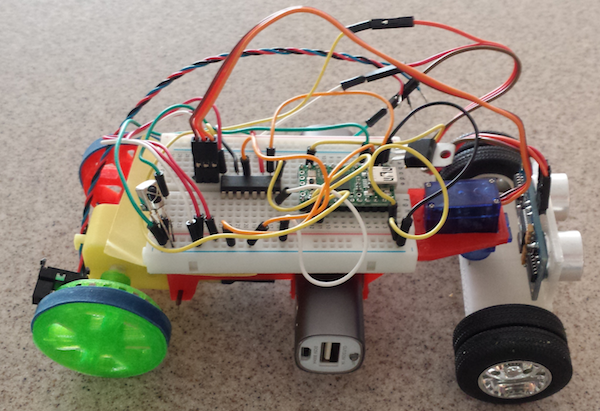

This spring I bought a refurb windows laptop because I needed a machine to take to maker events (like the library meetings) and run a 3D printer or an arduino or whatever. And the most recent version of Repetier that runs on a macbook is from 2013.

I had great dreams for that laptop: I was going to make it dual-boot Ubuntu, I was going to get a copy of Labview from Sparkfun… But no. I unpacked it. I let it download windows updates. I downloaded Firefox and cleaned off the desktop links to the most obvious bloatware. Then it rebooted and told me it had detected an imminent hard disk failure and to get my precious data off ASAP. I didn’t have any data on it yet, so I just booted it again, only to be informed that there was no hard disk present.

Luckily, the machine was still under the (short) refurb warranty, so I called, explained the problem (“my machine insists it has no disk”) and got a response: the company sent me a shipping box by 2-day air service so that I could return it.

A week or so later I got my laptop back, with a new hard disk and a promise that it had been extensively tested. Nuh-uh. It stayed up for an even shorter time. Not only an insistence there was no disk, but ostensibly not even the firmware to check whether there was a disk. Rinse and repeat (I was beginning to admire my collection of laptop shipping boxes).

The third time, I called in the morning and reached a tech who recommended I take out the battery and let the laptop sit for a while to dissipate bad karma or something. When I put the battery back in, lo and behold the machine booted successfully and remained working for several hours before announcing yet again that it was toast. So I called and got to another tech who gave me what he claimed was the number for people who could authorize a replacement. But that number went to a cheery voice menu system that said “If you have a problem, go away and try and find an answer on our web site.” So I called back, got another shipping box and enclosed a note saying “Don’t just replace the disk and send it back. You tried that already.”

Replacing the motherboard and the touch pad and performing more “extensive testing” apparently didn’t do the trick either. Sometimes no disk present, sometimes imminent disk failure, once windows decided that it had been pirated and copied to another pc and refused to boot. All the messages boiled down to “You Lose”.

So I called yet again and got a tech who seemed genuinely miffed that I wasn’t willing to spend a couple hours running through the troubleshooting tree with him, and finally agreed to “escalate” my case to the people who could authorized a replacement. I learned the trick to the voice menu system — in my naivete the first few times I called, I hadn’t thought to ignore everything the chirpy greetings said and just press “0” repeatedly until a human arrived. (Oh, and may I say that Up-tempo distorted Pachelbel’s Canon played at full volume seems designed to drive people on hold to hang up in fear for their eardrums, a little like those uncomfortable fast-food chairs, or the city benches with spikes on them? )

A few more tests of will and a round of phone/email tag, and the Case Manager went through the whole damn file again and tried to convince me to send my laptop in for service just one more time. But he folded pretty easily, and offered me a more-or-less equivalent new computer that maybe, just maybe won’t be a complete dog’s breakfast out of the box. I figure the difference between what I paid and the list price of the new machine is about half the value of the time I lost booting, configuring, rebooting, waiting on hold, packing, unpacking and generally tearing out my hair.

So when the new machine arrives, shall I start working with it, or try and fob it off on someone else and just go down to the local new-and-used computer emporium for something that I can trust?

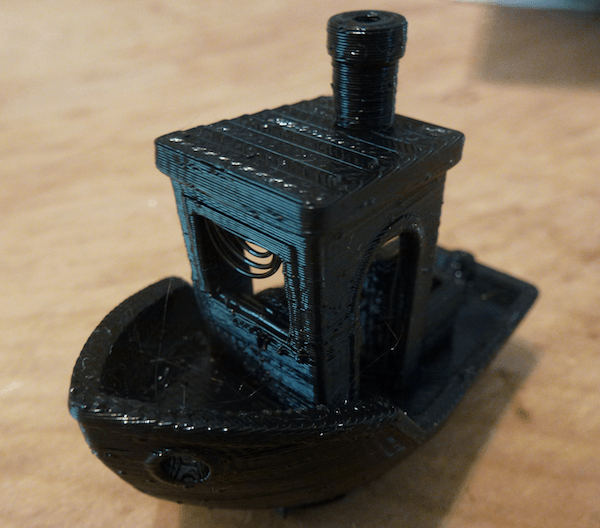

Does it cast enough photons to be useful? Maybe. I haven’t cranked it up to full power yet; I’m a bit scared. But at least it’s one less project cluttering up the workshop and my brain.

Does it cast enough photons to be useful? Maybe. I haven’t cranked it up to full power yet; I’m a bit scared. But at least it’s one less project cluttering up the workshop and my brain.